across Europe.

What Is Pharmaceutical Analytics?

At its core, pharmaceutical analytics means turning mountains of historical and real-time data into actionable insights. It covers:

- Descriptive analytics: What happened?

- Predictive analytics: What might happen?

- Prescriptive analytics: What should we do?

AI-powered predictive analytics uses machine learning models to spot patterns in reactor temperatures, pressure readings, batch records and more. The result? You can forecast deviations in yield, flag potential quality failures and plan maintenance before downtime strikes.

Why AI-Powered Predictive Analytics Matters

In an era of data overload, relying on manual checks and gut instinct isn’t enough. Here’s why:

- Data grows faster than ever.

- Legacy systems lack real-time visibility.

- Equipment failures can halt production for days.

- Regulatory audits demand precise records.

Pharmaceutical analytics with AI bridges these gaps. You get continuous monitoring, anomaly alerts and predictive models tailored to your process—and you can act fast.

Key Benefits of AI-Driven Pharmaceutical Analytics

1. Enhanced Yield and Productivity

Imagine spotting a subtle shift in reactor pressure that usually foreshadows a failed batch. AI models learn these signals by analysing historical batches. Early warnings let you adjust parameters—and rescue up to 95% of at-risk batches. More successful runs mean higher throughput and a healthier bottom line.

2. Consistent Quality Control

Variations in temperature or mixing speed can lead to off-spec products. With predictive analytics, you’ll:

- Detect process drifts in real time

- Trigger alarms before a full batch runs

- Automate corrective actions via closed-loop controls

The outcome? Fewer rejects, fewer recalls and better compliance.

3. Cost Reduction and Waste Minimisation

Excess materials, rework and unplanned stoppages can eat into profits. AI-driven pharmaceutical analytics identifies:

- Underutilised equipment

- Imbalanced inventories

- Downtime root causes

By forecasting maintenance needs and optimising raw-material usage, you’ll cut waste and operating costs.

4. Streamlined Compliance and Reporting

Regulators want transparent records. Predictive analytics platforms log every anomaly, calibration change and intervention. You’ll generate audit-ready reports in minutes—not months. That saves time and reduces risk of non-compliance penalties.

Real-World Use Cases

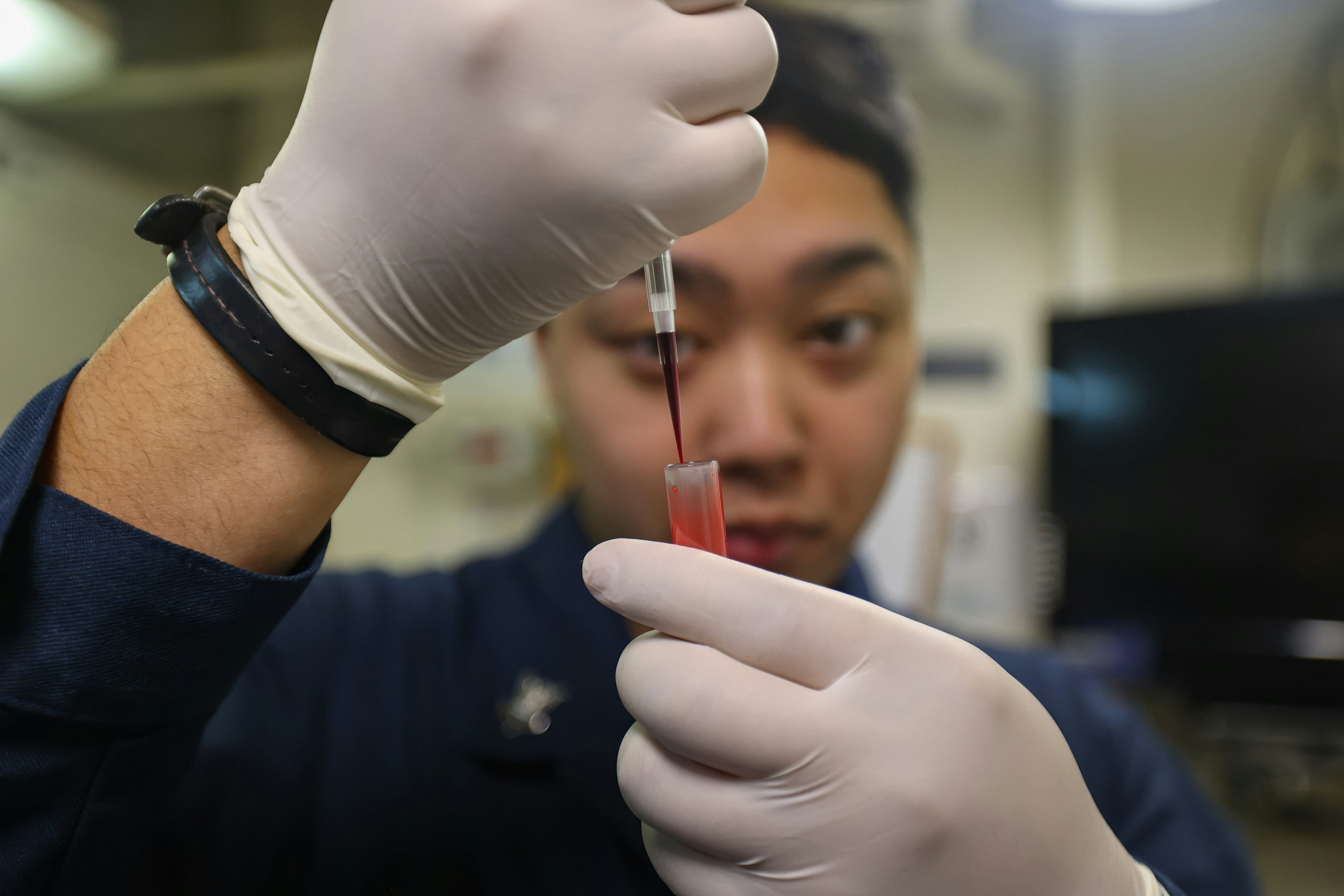

Predictive Maintenance for Production Equipment

- IoT sensors capture vibration, temperature and pressure data.

- AI models forecast when pumps or compressors need service.

- Maintenance teams act proactively, avoiding costly shutdowns.

In-Line Quality Monitoring with PAT

Process Analytical Technology (PAT) tools measure critical quality attributes on the fly. Machine learning models analyse those feeds to flag out-of-range readings. The result? Batch consistency and higher yields.

Demand Forecasting and Batch Planning

AI-based demand models consider historical sales, disease prevalence and market trends. This helps you decide which formulations to produce when—and how much. Better forecasting prevents under- or over-production.

Supply Chain Optimisation

Pharma supply chains are global and complex. Predictive analytics assesses variables like regional demand, shipping delays and raw-material shortages. You can then reroute orders or adjust production schedules to ensure on-time delivery.

Accelerated Process Development

Bringing a new drug from pilot to full-scale production is time-consuming. AI-driven analytics identifies optimal process parameters early, shrinking scale-up risks and timelines.

Introducing Smart Launch by ConformanceX

Most pharma companies still piece together multiple systems. That leads to data silos, delays and missed insights. Smart Launch is a unified platform that brings everything into one dashboard:

-

Real-Time Data Integration

Connect equipment, PAT sensors and ERP systems. All data streams feed your predictive models without manual imports. -

Customisable Predictive Models

Tailor algorithms to your reactors, mixers or packaging lines. Smart Launch adapts as your processes evolve. -

Competitive Intelligence

Monitor market dynamics, competitor launches and pricing shifts. Align production plans with commercial insights. -

Actionable Dashboards & Alerts

Get email or SMS notifications for anomalies. Dashboards show yield forecasts, maintenance schedules and compliance metrics at a glance.

Smart Launch’s AI-driven predictive analytics minimises launch risks and scales with your business. And since ConformanceX focuses on SMEs, you avoid the cost and complexity of enterprise-only solutions.

Traditional vs AI-Driven Pharmaceutical Analytics

| Aspect | Traditional Approach | AI-Driven with Smart Launch |

|---|---|---|

| Data Handling | Manual exports, spreadsheets | Automated real-time feeds |

| Batch Monitoring | Sample-based testing | Continuous in-line monitoring |

| Maintenance Scheduling | Calendar-based | Predictive, condition-driven |

| Quality Alerts | Post-batch review | Early anomaly detection |

| Compliance Reporting | Manual report generation | Audit-ready dashboards |

Tips for a Smooth Implementation

-

Conduct a Data Audit

Identify key data sources and gaps. Ensure your IoT sensors and control systems are feeding Smart Launch accurately. -

Start with a Pilot

Choose one reactor or packaging line. Validate predictive models and refine parameters. -

Form a Cross-Functional Team

Bring together manufacturing, IT and quality experts. Shared ownership accelerates adoption. -

Train and Upskill

Empower operators and engineers with hands-on workshops. Familiarity boosts confidence. -

Iterate and Improve

Use performance metrics to tweak models. Smart Launch evolves as you learn.

Overcoming Common Challenges

- Data Silos: Break down departmental barriers. Smart Launch integrates third-party systems and legacy equipment.

- Budget Constraints: Focus on quick wins—like maintenance savings—to build ROI.

- Skill Gaps: Partner with ConformanceX’s consultants. They guide your team through every step.

- Unrealistic Expectations: Set clear goals and KPIs. Predictive analytics isn’t magic; it’s data-driven progress.

Conclusion

The future of pharmaceutical manufacturing is powered by pharmaceutical analytics. AI-driven predictive models give you foresight on yield, quality and cost. They help you stay compliant and flexible in a fast-moving market. Smart Launch by ConformanceX delivers all these capabilities in a single platform designed for SMEs. Ready to boost your drug production, reduce waste and sharpen your competitive edge?

Call to Action:

Explore Smart Launch today.

Visit https://www.conformancex.com/ to get a personalised demo and start your free trial.